Why Choose Fineline Circuits & Technology for PCB Fabrication Service?

Fineline Circuits & Technology manufactures advanced PCB fabrication with consistent high quality and affordable pricing. Whether it is for prototype or large volume production runs, We can meet your PCB fabrication needs in a variety of materials and technologies. We focus on multi-layer, impedance controlled, and HDI PCB’s in varying complexities.

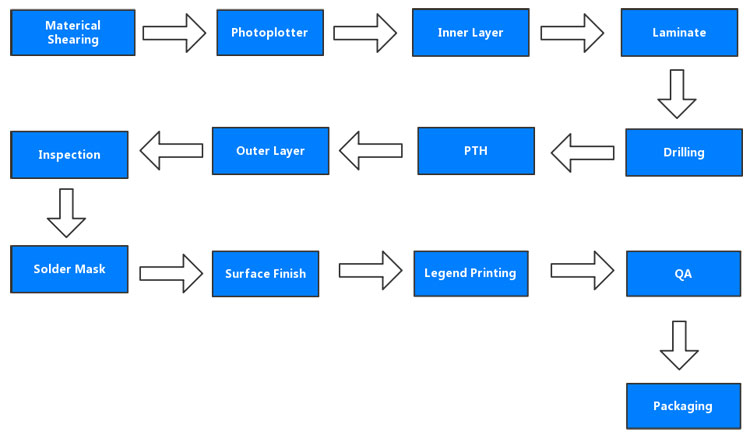

Our PCB Fabrication Process

Circuit Board Specifications

- Maximum Panel size: 24″ x 36″

- Maximum Number of Layers: 36

- Copper Thickness: 0.025oz to 20oz

- Minimum Line Width: 3mils

- Minimum Line spacing: 3mils

- Smallest Hole: 0.006″

- Micro & Laser Via

- Blind, Buried and plugged Vias

- Controlled impedance

- Depth Control/Cavity/Laser drilling

Material

- Thickness: 0.008″ to 0.500″

- High TG FR-4

- Polyimide

- PTFE, Duriod

- Aluminum Base

- Rogers

- Flex Laminate

- Embedded Resistors

- Or Any specialized material per your request

Solder Mask

- LPI – Green, Yellow, Black, Red, Blue etc.

- Peelable Mask

- Via Fill

- Copper fill

- Final Finishes

Surface Finish

- Carbon

- Selective Gold Plating

- Hard and Soft Gold

- Immersion Gold & Tin

- Immersion Silver & Palladium

- OSP

- Lead Free & Leaded Solder

Legend

- White

- Other colors per your request

Testing

- Electrical testing – Flying probe or Bed of Nails

- Sample lot inspection

- Cross-sectioning

Quality

- AOI

- 100% Visual inspection

Delivery

- Quick turn 24 to 48 Hours

- Standard Prototype: 5 to 15 days

- Standard Production: 10 to 20 days