Printed Circuit Board Assembly (PCBA) – Process, Technology, Tips and Techniques

Printed circuit board assembly, also known as PCBA, is the process of soldering or assembly of electronic components to a PCB or printed circuit board.

Printed circuit board assembly, also known as PCBA, is the process of soldering or assembly of electronic components to a PCB or printed circuit board. A circuit board prior to assembly of electronic components is known as PCB. Once electronic components are soldered, the board is called Printed Circuit Assembly (PCA) or Printed Circuit Board Assembly (PCBA). Different Manual and Automatic PCBA Tools are used in this process.

It has to be noted that assembly of a circuit board is different from manufacturing a circuit board. Manufacturing printed circuit boards involve several processes including PCB designing and creating PCB prototype Once a PCB is ready, electronic components need to be soldered onto it before it can be used in any electronic equipment or gadget. This assembly of electronic components depends on type of circuit board, type of electronic components and purpose of the circuit board.

Things Needed for Printed Circuit Board Assembly

Following electronics parts and consumables are needed for PCB assembly –

- Printed Circuit Board

- Electronic components

- Soldering materials including Solder wire, solder paste, solder bar, solder preforms (depending on the type of soldering to be done)

- Soldering flue

- Soldering equipment including soldering station, wave soldering machine, SMT equipment, inspection and testing equipment etc.

Once all of the above equipment, electronic parts and all raw materials are arranged, it is time to start the printed circuit board assembly process.

Printed Circuit Board Assembly with Thru-Hole Electronic Components

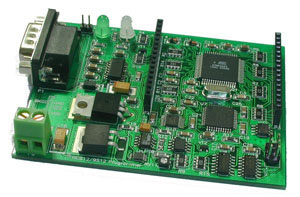

Printed Circuit Board Assembly

Electronic components that have leads coming out and are inserted through tiny holes in the PCB for soldering are called thru-hole electronic components. The assembly or soldering process for these components include wave soldering and hand soldering – Wave Soldering – A PCB assembly process in which solder in the form of solder bar are put in a high-temperature bath. This solder remains in the bath in molten form and forms a wave at very high temperature. The range of temperature depends on the type of solder. Traditional tin / lead (Sn/Pb) solder has lower melting point than lead free (Pb-Free) solder. The PCB with all the thru-hole electronic components in holes is passed over molted solder with a help of a conveyor belt. The whole wave soldering process includes following steps:

- Inserting of electronic components

- Flux application

- Preheat

- Wave Solder

- Cleaning

- Testing

Once the wave soldering is done, the Printed Circuit Board Assembly or PCBA is cleaned and tested. If any fault or solder joint defect is found, it is sent for rework, which is generally done by hand. Hand Soldering is done in manufacturing units with less work load or in rework / repair jobs. A good quality soldering station or soldering iron and solder wire and flux are used in the process.

Surface Mount Technology (SMT) for Printed Circuit Board Assembly

Surface Mount Technology or SMT is a PCB assembly process for SMD electronic components. SMD components don’t have leads or legs. They are mounted on the surface of the circuit board. The equipment, electronic components and other soldering material used in this assembly process is different from thru-hole soldering process.

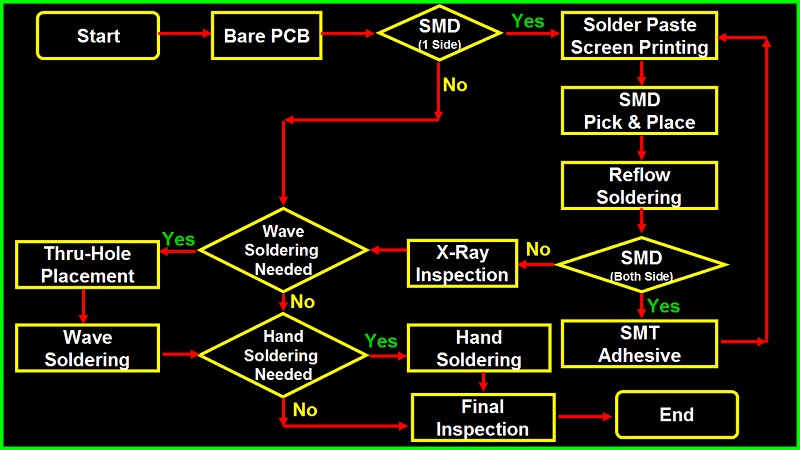

PCB Assembly Process Flow Chart (PCBA Process)